CNCコントローラー市場調査レポート、規模とシェア、成長機会、および傾向洞察分析―製品別、コンポーネント別、軸タイプ別、アプリケーション別、エンドユーザー別、および地域別―世界市場の見通しと予測 2025―2037 年

出版日: Oct 2024

- 2020ー2024年

- 2025―2037 年

- 必要に応じて日本語レポートが入手可能

CNCコントローラー市場規模

CNCコントローラー市場に関する当社の調査レポートによると、市場は2025-2037年の予測期間中に約9%のCAGRで成長すると予想されています。将来の年には、市場は約80億米ドルの価値に達する見込みです。しかし、当社の調査アナリストによると、基準年の市場規模は約40億米ドルと記録されています。CNCコントローラーに関する当社の市場調査によると、アジア太平洋地域市場は予測期間中に約 45% の圧倒的な市場シェアを保持すると予想されており、一方、北米市場は今後数年間で有望な成長機会を示す準備が整っています。これは主に、世界の製造業における産業自動化の採用の増加の結果です。

CNCコントローラー市場分析

CNCコントローラーが導入される前は、工作機械は熟練した訓練を受けた機械工によって手動で操作されていましたが、人間が関与するため、生産に一貫性や不正確さが生じていました。測定値の設定、パスの切断、速度の制御における人的ミスにより、製品の品質が低下し、不合格率が高くなることがよくありました。

- 当社の市場調査レポートによると、手作業による機械加工では精度に最大 0.01 インチのばらつきが生じる可能性があり、非常に厳しい公差が要求される航空宇宙や自動車などの業界には不十分でしました。

さらに、生産性が低く、労働力への依存度が高いことも、CNCコントローラーの注目を集めたもう 1 つの理由でしました。これは、従来の機械加工では、熟練したオペレーターが複数の機械を制御する必要があり、生産速度と拡張性が制限されていたからです。各マシンはさまざまなジョブに合わせて手動で調整する必要があり、最終的には動作が遅くなり、タスク間のダウンタイムが増加しました。これにより、CNCコントローラーに対する強い需要が生まれました。

- 当社の市場見通しによれば、手動作業は自動化作業の 2-3 倍の労働システムを必要とし、CNCコントローラーの導入により工場の生産性が最大 35% 向上すると予想されていました。

しかし、日本の航空宇宙産業の発展は、業界が複数のタスクで CNCコントローラーに大きく依存しているため、CNCコントローラーに対する膨大な需要を生み出しています。航空宇宙産業の成長は、国内の CNCコントローラーの需要に直接影響を与えています。

当社のCNCコントローラー市場分析調査レポートによると、次の市場傾向と要因が市場成長に貢献すると予測されています:

- 製造における自動化の拡大―製造における自動化の推進は、CNCコントローラー市場の拡大の主要な成長原動力です。世界中の業界が、複雑なプロセスを自動化し、効率を向上させるために最先端の CNC システムを採用しています。 CNCコントローラーは、人間の介入を最小限に抑えながら機械が高精度のタスクを実行できるようにすることで、自動化において重要な役割を果たしており、製造工場には欠かせないものとなっています。

- SDKI Analytics の調査者による市場見通しによると、産業用ロボットの運用ストックは過去 10 年間で 3 倍に増加し、2023 年には多数の業界で 4百万台を超えるロボットが使用されており、CNCコントローラー市場シェアの成長見通しが生まれています。

- 精密エンジニアリングの需要の増加―自動車製造、航空宇宙、エレクトロニクスなどの業界における精密エンジニアリングの需要の高まりに伴い、先進的な CNCコントローラーの採用が大幅に増加しています。精密エンジニアリングの成長傾向は、CNCコントローラーの市場に影響を与えています。さらに、政府の支援と先進製造業への投資により、市場拡大にさらに弾みがついています。

CNCコントローラー市場は日本の市場プレーヤーにどのような利益をもたらしますか?

日本には強固な製造インフラがあり、高度な精密エンジニアリングと堅固な産業機械部門で知られており、CNCコントローラーの重要な消費者となっています。FANUC、Yaskawa Electricなどの主要市場プレーヤーは、最先端のコントローラー市場で確立されたプレーヤーです。

- 当社の調査者によると、日本は第 3 位であり、世界の総製造生産高の 7.5% 以上を供給しており、その大部分は精密作業のための CNC テクノロジーに依存しています。

さらに、日本政府は製造業のイノベーションと自動化を促進する政策を実施しています。たとえば、Society 5.0 イニシアチブでは、高性能 CNC システムなどのハイエンド テクノロジーの製造への統合が強調されています。これは製造における自動化と連携し、多軸 CNCコントローラーの使用を奨励して生産性と精度を向上させます。

- さらに、日本市場プレーヤーによる進歩と躍進により、CNCコントローラー市場はさらに強化されます。たとえば、Mazakはスマート製造とインダストリー 4.0 への重点分野でリードしています。同社は、インテリジェントな機械監視システムとハイブリッド製造技術を提供します。スマート主導の洞察と自動化に重点を置いているため、同社は運用の生産性と効率を向上させる主要なイノベーターとなっています。このようなイノベーションは、日本の CNCコントローラー市場を押し上げる態勢が整っています。

市場課題

最先端のCNCコントローラーの操作には専門的なスキルが必要であり、訓練を受けた人材の不足がCNCコントローラー市場の拡大に対する大きな制約となっています。このスキルギャップは、適切な専門知識がなければ CNCコントローラーを完全に活用することが困難になる可能性があるため、製造分野での自動化の導入を検討している業界にとって大きな課題となります。

サンプル納品物ショーケース

- 調査競合他社と業界リーダー

- 過去のデータに基づく予測

- 会社の収益シェアモデル

- 地域市場分析

- 市場傾向分析

CNCコントローラー市場レポートの洞察

|

レポートの洞察 |

|

|

CAGR |

9% |

|

2024 年の市場価値 |

約40億米ドル |

|

2037 年の市場価値 |

約80億米ドル |

CNCコントローラー市場セグメンテーション

当社は、CNCコントローラー市場の見通しに関連するさまざまなセグメントにおける需要と機会を説明する調査を実施しました。当社は、製品別、コンポーネント別、軸タイプ別、アプリケーション別、およびエンドユーザー別ごとに市場を分割しました。

CNCコントローラー市場は、軸タイプに基づいて、2軸、3軸、4軸、5軸、多軸に分割されています。このうち、5軸のセグメントは、生産時間の短縮と高効率の実現により、予測期間中に最大の市場シェアを約 40% 保持すると予想されます。5軸 CNCコントローラーは、5 軸にわたる同時動作を可能にし、複数のセットアップの必要性を排除することで生産時間を短縮できます。この効率性により、費用対効果が高まり、生産サイクルが短縮されます。

- 当社の市場調査レポートによると、5軸 CNC システムは生産効率を 25% 以上向上させることができ、高性能産業にとって理想的な選択肢となっています。

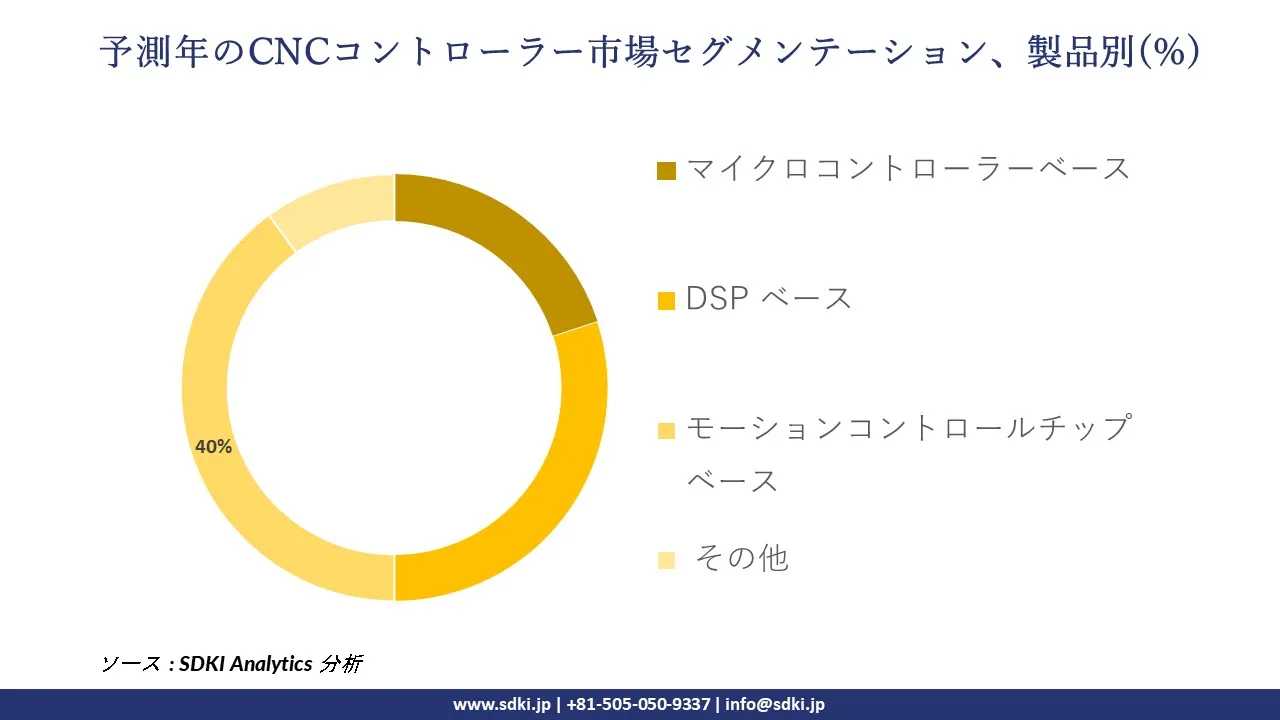

さらに、CNCコントローラー市場は、製品に基づいて、マイクロコントローラーベース、DSP ベース、モーションコントロールチップベース、その他に分割されています。これらのうち、モーションコントロールチップベースセグメントは、予測期間中に約 40% のより大きな市場シェアを保持するはずです。これは、高性能 CNC システムでの採用が増加しているためです。モーションコントロールチップは、シームレスで正確な多軸動作を可能にし、大幅な成長が期待できるセグメントを確立するため、高性能 CNC システムに不可欠です。

|

製品 |

|

|

コンポーネント |

|

|

軸タイプ |

|

|

アプリケーション |

|

|

エンドユーザー |

|

CNCコントローラー市場の傾向分析と将来予測:地域市場の見通しの概要

アジア太平洋地域の CNCコントローラー市場は、製造における自動化の大幅な拡大により、約45% 以上のシェアを獲得して市場をリードすると予測されています。アジア太平洋諸国、主に中国と韓国は自動化に投資しています。 CNCコントローラー、特に高度な CNCコントローラーは、この変革において重要な役割を果たします。

- 当社の市場調査レポートによると、世界の製造生産高の 30% 以上を占める中国は自動化に注力しており、CNC 市場の成長を推進しています。自動車製造、エレクトロニクス、その他の分野のタスクに精度をもたらすために、多軸 CNCコントローラーを導入する業界が増えています。

日本のCNCコントローラー市場は、高度な精密エンジニアリング能力を必要とする自動車製造や航空宇宙用CNCなどのハイテク分野における日本の優位性の結果、拡大する傾向にあります。この精度の需要は自動およびロボット分野で非常に高く、CNCコントローラー市場の収益を押し上げる可能性があります。

- 当社の調査者は、市場調査レポートで、日本がロボット製造の世界リーダーであり、世界のロボット生産の 40% 以上を占めており、精密エンジニアリング機能を備えた CNCコントローラーの需要に影響を与えていることを発見しました。

|

|

|

ヨーロッパ |

|

|

アジア太平洋地域 |

|

|

ラテンアメリカ |

|

|

中東とアフリカ |

|

北米では、CNCコントローラーの市場は、政府の取り組みと先進的な製造技術への投資により、大幅な成長を遂げます。CNC システムを含む製造技術の革新に資金を提供する「Manufacturing USA」などの取り組みは、この地域の市場全体の成長に利益をもたらす可能性があります。

CNCコントローラー調査の場所

北米(米国およびカナダ)、ラテンアメリカ(ブラジル、メキシコ、アルゼンチン、その他のラテンアメリカ)、ヨーロッパ(英国、ドイツ、フランス、イタリア、スペイン、ハンガリー、ベルギー、オランダおよびルクセンブルグ、NORDIC(フィンランド、スウェーデン、ノルウェー) 、デンマーク)、アイルランド、スイス、オーストリア、ポーランド、トルコ、ロシア、その他のヨーロッパ)、ポーランド、トルコ、ロシア、その他のヨーロッパ)、アジア太平洋(中国、インド、日本、韓国、シンガポール、インドネシア、マレーシア) 、オーストラリア、ニュージーランド、その他のアジア太平洋地域)、中東およびアフリカ(イスラエル、GCC(サウジアラビア、UAE、バーレーン、クウェート、カタール、オマーン)、北アフリカ、南アフリカ、その他の中東およびアフリカ

競争力ランドスケープ

CNCコントローラー業界の概要と競争のランドスケープ

SDKI Analyticsの調査者によると、CNCコントローラー市場見通しは、大企業と中小規模の組織といったさまざまな規模の企業間の市場競争により細分化されています。調査報告書では、市場関係者は製品や技術の発売、戦略的パートナーシップ、コラボレーション、買収、拡張など、あらゆる機会を利用して市場全体の見通しでの競争優位性を獲得しています。

当社の調査レポートによると、世界のCNCコントローラー市場の成長に重要な役割を果たす主要な主要企業には、Siemens AG、Bosch Rexroth AG、Hurco Companies Inc.、Fagor Automation、Haas Automation, Inc.などが含まれます。 さらに、市場見通しによると、日本のCNCコントローラー市場のトップ5プレーヤーは、DMG MORI CO., LTD.、Mitsubishi Electric Corporation、Okuma Corporation、FANUC CORPORATION、YAMAZAKI MAZAK CORPORATIONなどです。この調査には、世界のCNCコントローラー市場分析調査レポートにおける詳細な競合分析、企業概要、最近の動向、およびこれらの主要企業の主要な市場戦略が含まれています。

CNCコントローラー市場ニュース

- 2024年9月、Brother Industries, Ltd は、ダイカスト部品のバリ取りに特化した「SPEEDIO DG-1 バリ取りセンター」を発売しました。

- 2024 年 3 月、FANUC America は、最新の PLC/CNC 一体型モーション コントローラーを発売し、業界での進歩を遂げました。

CNCコントローラー主な主要プレーヤー

主要な市場プレーヤーの分析

日本市場のトップ 5 プレーヤー

目次

CNCコントローラーマーケットレポート

関連レポート

よくある質問

- 2020ー2024年

- 2025―2037 年

- 必要に応じて日本語レポートが入手可能